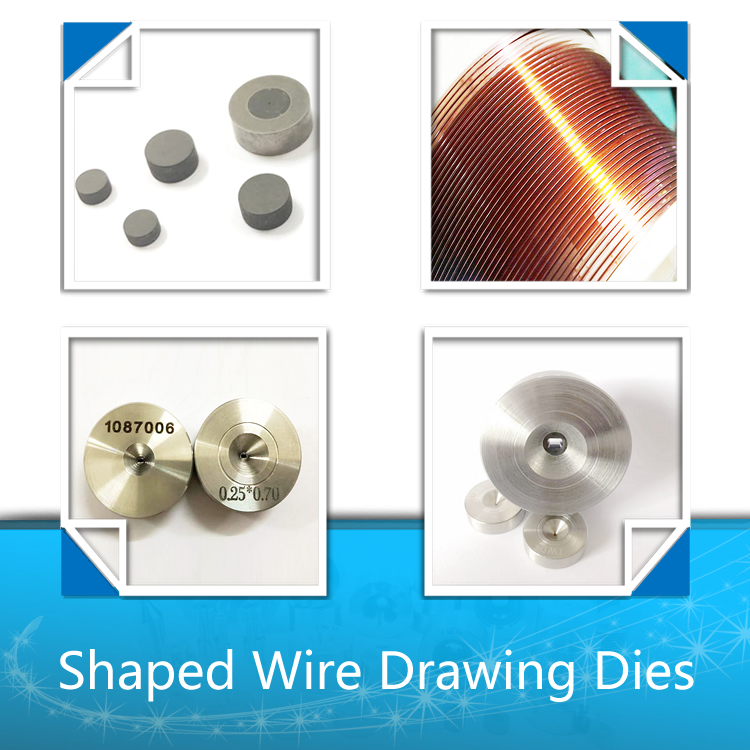

The minimum square hole is 0.18x0.18mm,the flat square hole is 0.08 × 0.20 mm,the semicircular line eye is 0.20 × 0.40mm,the triangle line eye is 0.25x0.25mm,the sharp angle can reach 0.01mm,the tolerance is about ± 0.001mm,and other specifications and shapes can be customized according to customer requirements.

| Product Name | PCD Shaped Dies; Diamond Shaped Dies; PCD Shaped Drawing Dies; PCD Shaped Wire Dies; Shaped Diamond Wire Drawing Dies |

| Hole Sizes | The minimum square hole is 0.18x0.18mm,the flat square hole is 0.08 × 0.20 mm,the semicircular line eye is 0.20 × 0.40mm,the triangle line eye is 0.25x0.25mm,the sharp angle can reach 0.01mm,the tolerance is about ± 0.001mm,and other specifications and shapes can be customized according to customer requirements. |

| Applications | copper wire such as flat wire,decorative products,such as copper wire used in automobile alternator. |

| Advantages | Diamond Shaped Dies can produce square,flat square, triangle,hexagon,octagonal,semicircle,ellipse,fan,Z-shaped,tile shaped and other special-shaped drawing dies. |

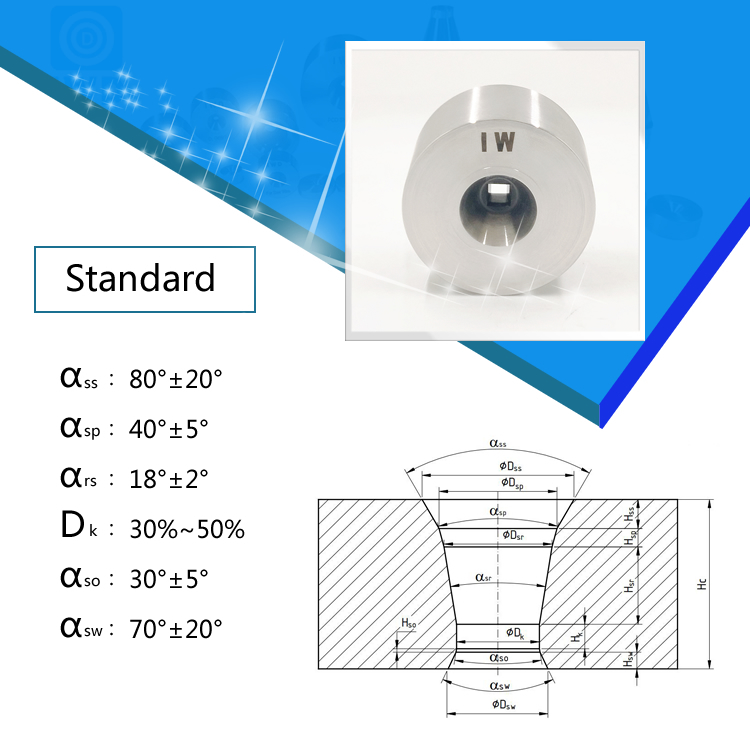

| α(ss)Entrance | The inlet area is polished so that the drawing fluid can circulate smoothly |

| α(sp)Approach | The lubrication area is finely polished, so that the wire can be easily excessive |

| α(rs)Reduction | The working area can reduce the drawing force, and the change-point contact is face-to-face angle drawing, which reduces friction and die wear. The deformed structure is more reasonable and stable. The upper line can be drawn smoothly when the incoming line becomes thicker or thinner. |

| d(k)Bearing | The fixed warp area can ensure the precise diameter, smoothness and out-of-roundness of the wire for a long time. |

| α(so)Back Relief | The safety angle can ensure that the wire is drawn without scratches, and the life expectancy tends to be longer. |

| α(sw)Exit | The deepening of the outlet can greatly support the tensile stress of the outlet. |

Wire drawing is done by passing the metal wire through the hole of the Wire Drawing Die, and applying a pulling force to the wire at the exit side of the die. The wire is contracted and squeezed in the die cavity and gradually becomes thinner, and its speed increases near the exit of the die hole. Since the volume of the wire is constant, the decrease in cross section makes it stretched. In the center, there is a hole of a certain shape, such as round, square, octagonal or other special shapes. When the metal is pulled through the die hole, the size becomes smaller and even the shape changes.

The best material depends on the wire you draw and the quantity you draw. Contact us to help you choose the most economical solution and reduce the total cost of ownership of your drawing dies.

Tolerance

Diameter(inch) | Diameter(mm) | Tolerance(mm) | Roundness(mm) |

≤0.00157 | ≤0.040 | 0.0003 | 0.0002 |

0.00158-0.00393 | 0.041-0.099 | 0.0005 | 0.0003 |

0.00394-0.01968 | 0.100-0.499 | 0.001 | 0.0005 |

0.01969-0.03936 | 0.500-0.999 | 0.0015 | 0.0008 |

0.03937-0.05905 | 1.000-1.499 | 0.002 | 0.001 |

0.05906-0.08661 | 1.500-2.199 | 0.003 | 0.0015 |

0.08662-0.12992 | 2.200-3.299 | 0.004 | 0.002 |

0.12993-0.18110 | 3.300-4.599 | 0.005 | 0.0025 |

0.18111-0.22834 | 4.600-5.799 | 0.006 | 0.003 |

0.22835-0.29921 | 5.800-7.599 | 0.007 | 0.0035 |

0.18111-0.41338 | 4.600-10.499 | 0.008 | 0.004 |

PCD Dies with IWD PCD Blanks

inches | mm | ADDMA | IWD | Maximum Diameter |

0.0039-0.0157 | 0.100-0.400 | D6 | IWD3210 | 0.4 |

0.0079-0.0315 | 0.200-0.800 | D12 | IWD3215 | 0.8 |

0.0079-0.0394 | 0.200-1.000 | D12 | IWD4215 | 1.0 |

0.0197-0.0591 | 0.500-1.500 | D15 | IWD5225 | 1.5 |

0.0197-0.0591 | 0.500-1.500 | D15 | IWD4223 | 1.5 |

0.0315-0.0787 | 0.800-2.000 | D18 | IWD5235 | 2.0 |

0.0315-0.0787 | 0.800-2.000 | D18 | IWD4229 | 2.0 |

0.0472-0.1181 | 1.200-3.100 | D21 | IWD7240 | 3.1 |

0.0472-0.1181 | 1.200-3.100 | D21 | IWD6838 | 3.1 |

0.0591-0.1732 | 1.500-4.400 | D24 | IWD9553 | 4.4 |

0.0591-0.1732 | 2.000-4.400 | D24 | IWD6853 | 4.4 |

0.1299-0.2126 | 3.300-5.400 | D27 | IWD1285 | 5.4 |

0.1299-0.2183 | 3.300-5.800 | D27 | IWD12987 | 5.8 |

0.2008-0.2992 | 5.100-7.600 | D30 | IWD12912 | 7.6 |

0.3150-0.4331 | 8.000-11.000 | D33 | IWD15215 | 11.0 |

0.3150-0.4409 | 8.000-11.200 | D30 | IWD18213 | 11.2 |

0.3150-0.4724 | 8.000-12.000 | D33 | IWD18215 | 12.0 |

0.3150-0.4921 | 8.000-12.500 | D33 | IWD18217 | 12.5 |

0.3150-0.5000 | 8.000-12.700 | D36 | IWD18218 | 12.7 |

The above hole sizes are recommended for soft wire.In case of hard wire drawing,the maximum hole size should not exceed 65% of them.

Customized Design And Processing PCD Shaped Wire Drawing Die,Copper Wire Drawing Polycrystalline Diamond Shaped Wire Drawing Dies

The polycrystalline profiled wire drawing die is made of high quality die core,which has the advantages of uniform texture, strong wear resistance,high finish,high precision and long service life.

The surface finish and accuracy of wire rod can be ensured in the long-time drawing process.

The profiled die is used by drawing and extruding the material under pressure through the die head.

They accurately produce products of various shapes,such as connecting flat cables,to meet the diverse needs of customers.

The wire drawing die is a very important and consumable product used by various metal wire manufacturers to draw wires. The application range of wire drawing dies is very wide, mainly used for drawing straight and difficult-to-machine objects such as bars, wires, wires, pipes, etc., and generally suitable for drawing processing operations of metal and alloy materials such as steel, copper, tungsten, molybdenum, etc. . Since the cost of the wire drawing die can reach more than half of the wire drawing cost, how to reduce the consumption cost of the wire drawing die and increase its service life is the primary problem that metal wire production units urgently need to solve.

Wire Drawing Dies have a wide range of uses, such as: high-precision wires used in electronic devices, radars, televisions, instruments and aerospace, as well as commonly used tungsten wires, molybdenum wires, stainless steel wires, wire and cable wires and various alloy wires, all of which are made of diamond It is drawn by a wire drawing die. Due to the use of natural diamond as the raw material, the diamond wire drawing die has strong wear resistance and extremely long service life.

Contact: Jeff Liu

Phone: 180 0383 7191

Tel: 0371-8608 2760

Email: sales@iwdiamond.com

Add: 17-1,No.73,Duying Street,High-New Tech Zone,Zhengzhou,Henan,450001,China