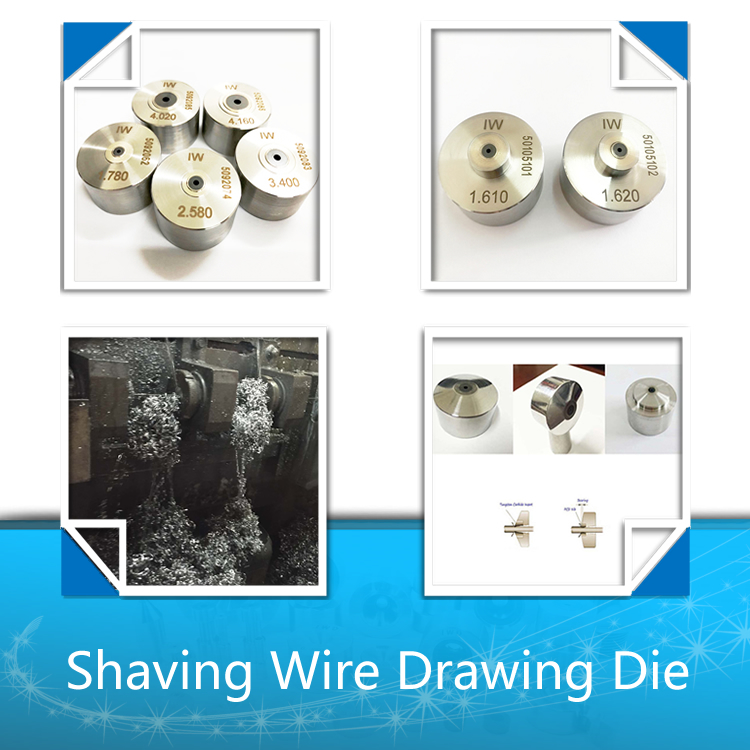

Blank Type: Polycrystalline Diamond,Tungsten steel,

Tungsten carbide (TC) insertion mold is widely used in peeling applications,but TC peeling mold is not relatively life-long,and the smooth surface and high-precision control performance are good.

Polycrystalline diamond (PCD) is a better choice,which has been proven to provide excellent surface finish and improved consistency for different wire materials.

| Product Name | PCD Shaving Dies; PCD Peeling Dies; Polycrystalline Diamond Shaving Dies; Diamond Shaving Dies |

| Blank Type | Polycrystalline Diamond, Tungsten steel |

| Applications | Copper wire,aluminum wire,gold wire,titanium alloy wire,etc.that require wire surface shaved. |

| Advantages | TC Shaving Dies Advantages:dies cost cheap. Disadvantages:short lifetime,poor consistency of wire,surface defects,high temperature. PCD Shaving Dies Advantages:long lifetime,good consistency,high wear resistance and impact resistance. Disadvantages:Higher unit prices,longer lead time. |

Polycrystalline Diamond (PCD) is a better choice,which has been proven to provide excellent surface finish and improved consistency for different wire materials.

Tungsten Carbide (TC) insertion mold is widely used in peeling applications,but TC peeling dies is not relatively life-long,and the smooth surface and high-precision control performance are good.

The load-bearing area of polycrystalline diamond (PCD) peeling dies supports the vibration of wire material.It is much better to peel the wire surface through PCD dies than by a TC peeling dies.

The bearing area of PCD Shaving Dies support shaved wire materials against the vibration,the wire surface shaved by a PCD die is much better than that shaved by a TC dies.

The lifetime of PCD Shaving Dies provide 20 to 80 times (depending on materials) longer tool life than TC shaving dies.The long life reduces the setup time of exchange dies.

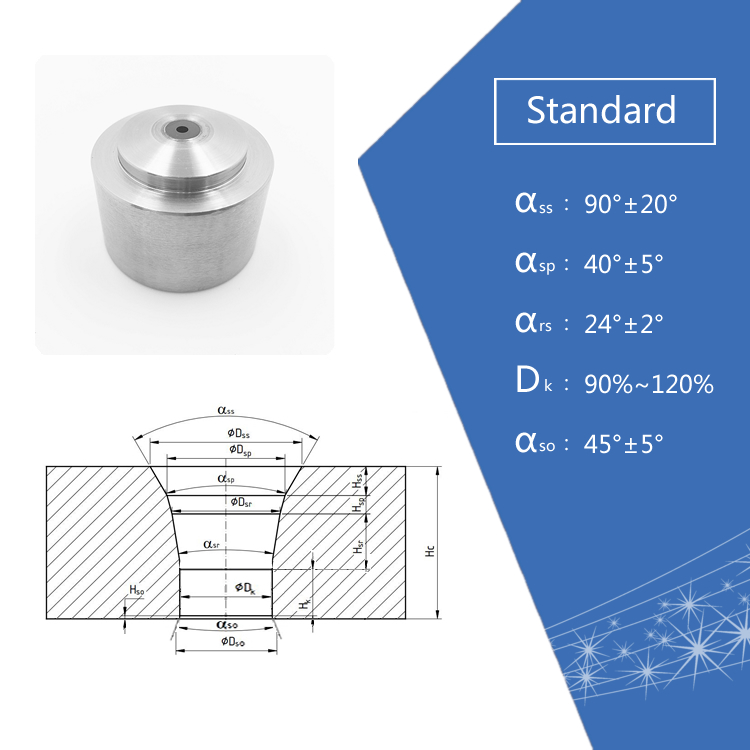

| α(ss)Entrance | The inlet area is polished so that the drawing fluid can circulate smoothly |

| α(sp)Approach | The lubrication area is finely polished, so that the wire can be easily excessive |

| α(rs)Reduction | The working area can reduce the drawing force, and the change-point contact is face-to-face angle drawing, which reduces friction and die wear. The deformed structure is more reasonable and stable. The upper line can be drawn smoothly when the incoming line becomes thicker or thinner. |

| d(k)Bearing | The fixed warp area can ensure the precise diameter, smoothness and out-of-roundness of the wire for a long time. |

| α(so)Back Relief | The safety angle can ensure that the wire is drawn without scratches, and the life expectancy tends to be longer. |

| α(sw)Exit | The deepening of the outlet can greatly support the tensile stress of the outlet. |

Wire drawing is done by passing the metal wire through the hole of the Wire Drawing Die, and applying a pulling force to the wire at the exit side of the die. The wire is contracted and squeezed in the die cavity and gradually becomes thinner, and its speed increases near the exit of the die hole. Since the volume of the wire is constant, the decrease in cross section makes it stretched. In the center, there is a hole of a certain shape, such as round, square, octagonal or other special shapes. When the metal is pulled through the die hole, the size becomes smaller and even the shape changes.

The best material depends on the wire you draw and the quantity you draw. Contact us to help you choose the most economical solution and reduce the total cost of ownership of your drawing dies.

Tolerance

Diameter(inch) | Diameter(mm) | Tolerance(mm) | Roundness(mm) |

≤0.00157 | ≤0.040 | 0.0003 | 0.0002 |

0.00158-0.00393 | 0.041-0.099 | 0.0005 | 0.0003 |

0.00394-0.01968 | 0.100-0.499 | 0.001 | 0.0005 |

0.01969-0.03936 | 0.500-0.999 | 0.0015 | 0.0008 |

0.03937-0.05905 | 1.000-1.499 | 0.002 | 0.001 |

0.05906-0.08661 | 1.500-2.199 | 0.003 | 0.0015 |

0.08662-0.12992 | 2.200-3.299 | 0.004 | 0.002 |

0.12993-0.18110 | 3.300-4.599 | 0.005 | 0.0025 |

0.18111-0.22834 | 4.600-5.799 | 0.006 | 0.003 |

0.22835-0.29921 | 5.800-7.599 | 0.007 | 0.0035 |

0.18111-0.41338 | 4.600-10.499 | 0.008 | 0.004 |

PCD Dies with IWD PCD Blanks

inches | mm | ADDMA | IWD | Maximum Diameter |

0.0039-0.0157 | 0.100-0.400 | D6 | IWD3210 | 0.4 |

0.0079-0.0315 | 0.200-0.800 | D12 | IWD3215 | 0.8 |

0.0079-0.0394 | 0.200-1.000 | D12 | IWD4215 | 1.0 |

0.0197-0.0591 | 0.500-1.500 | D15 | IWD5225 | 1.5 |

0.0197-0.0591 | 0.500-1.500 | D15 | IWD4223 | 1.5 |

0.0315-0.0787 | 0.800-2.000 | D18 | IWD5235 | 2.0 |

0.0315-0.0787 | 0.800-2.000 | D18 | IWD4229 | 2.0 |

0.0472-0.1181 | 1.200-3.100 | D21 | IWD7240 | 3.1 |

0.0472-0.1181 | 1.200-3.100 | D21 | IWD6838 | 3.1 |

0.0591-0.1732 | 1.500-4.400 | D24 | IWD9553 | 4.4 |

0.0591-0.1732 | 2.000-4.400 | D24 | IWD6853 | 4.4 |

0.1299-0.2126 | 3.300-5.400 | D27 | IWD1285 | 5.4 |

0.1299-0.2183 | 3.300-5.800 | D27 | IWD12987 | 5.8 |

0.2008-0.2992 | 5.100-7.600 | D30 | IWD12912 | 7.6 |

0.3150-0.4331 | 8.000-11.000 | D33 | IWD15215 | 11.0 |

0.3150-0.4409 | 8.000-11.200 | D30 | IWD18213 | 11.2 |

0.3150-0.4724 | 8.000-12.000 | D33 | IWD18215 | 12.0 |

0.3150-0.4921 | 8.000-12.500 | D33 | IWD18217 | 12.5 |

0.3150-0.5000 | 8.000-12.700 | D36 | IWD18218 | 12.7 |

The above hole sizes are recommended for soft wire.In case of hard wire drawing,the maximum hole size should not exceed 65% of them.

Diamond Shaving Dies

Factory Price Polycrystalline Diamond Wire Drawing Dies;PCD Shaving Die With Long Drawing Life

Blank Type: Polycrystalline Diamond,Tungsten steel,

Tungsten carbide (TC) insertion mold is widely used in peeling applications,but TC peeling mold is not relatively life-long,and the smooth surface and high-precision control performance are good.

Polycrystalline diamond (PCD) is a better choice,which has been proven to provide excellent surface finish and improved consistency for different wire materials.

Contact: Jeff Liu

Phone: 180 0383 7191

Tel: 0371-8608 2760

Email: sales@iwdiamond.com

Add: 17-1,No.73,Duying Street,High-New Tech Zone,Zhengzhou,Henan,450001,China